By Mike Walmsley, Manager Product Management, TE Connectivity

Staying up to speed with the rapid evolution of “next-gen” products and standards for OpenVPX architecture can be challenging for designers of military embedded systems. That’s because the OpenVPX platform is quickly evolving, with new VITA standards featuring product innovations that provide significant benefits, namely:

- Faster processor and signal speeds;

- Shrinking size and weight;

- Standardized solutions that reduce the need for time-consuming and costly customization.

OpenVPX Progress

Introduced in 2004, the VPX designation was formally defined by the VMEbus International Trade Association (VITA) organization as the VITA 46 standard. Compared to the earlier VMEbus standard, VPX provides for far greater bandwidth by defining physical features of high-speed connectors over multiple physical links (i.e., switched fabrics). In 2009, the OpenVPX Industry Working Group began developing OpenVPX standards to define system-level VPX interoperability between modules as well as from modules to the backplane and chassis.

In 2017, the OpenVPX System Standard (ANSI/VITA 65-2017) was updated to support versatile system architectural solutions for VPX. New VITA-compliant technologies supporting OpenVPX include new RF and optical interconnects, card form factors and cabling options.

Developments in OpenVPX Interconnects

VITA 46 defines the primary digital connector for VPX and is based on TE Connectivity’s (TE’s) MULTIGIG RT platform to enable high-speed communication in compliant systems. Recently, that connector platform has evolved with more rugged and faster connector solutions, resulting in two supplemental VITA 46 standards addressing these faster speeds:

- VITA 46.30 standard will define VPX connectors with smaller compliant pin tails that support data rates to 25 Gb/s and higher.

- VITA 46.31 standard will define comparable connectors with short solder tails for soldering into blind vias in the printed circuit boards.

Keeping in line with these evolving standards, TE recently introduced the MULTIGIG RT 3 family that supports 25+ Gb/s baud rates, while maintaining mating compatibility with legacy VITA 46 connectors. The quad-redundant contacts of these ruggedized connectors ensure they can still withstand extreme military and space environments, while providing increased data throughput to meet newer system requirements.

VITA 67 (ANSI/VITA 67.0-2019) defines the coaxial interconnect base standard for VPX. Coax contacts are populated in multi-position modules to enable RF signaling between VPX plug-in modules and the chassis backplane pass-through interface. Electronic warfare (EW) and signal intelligence (SIGINT) processing are demanding higher frequency RF signaling and military designers want higher density in VITA 67 RF modules. Accordingly, a new VITA 67.3 revision includes two new higher density interfaces.

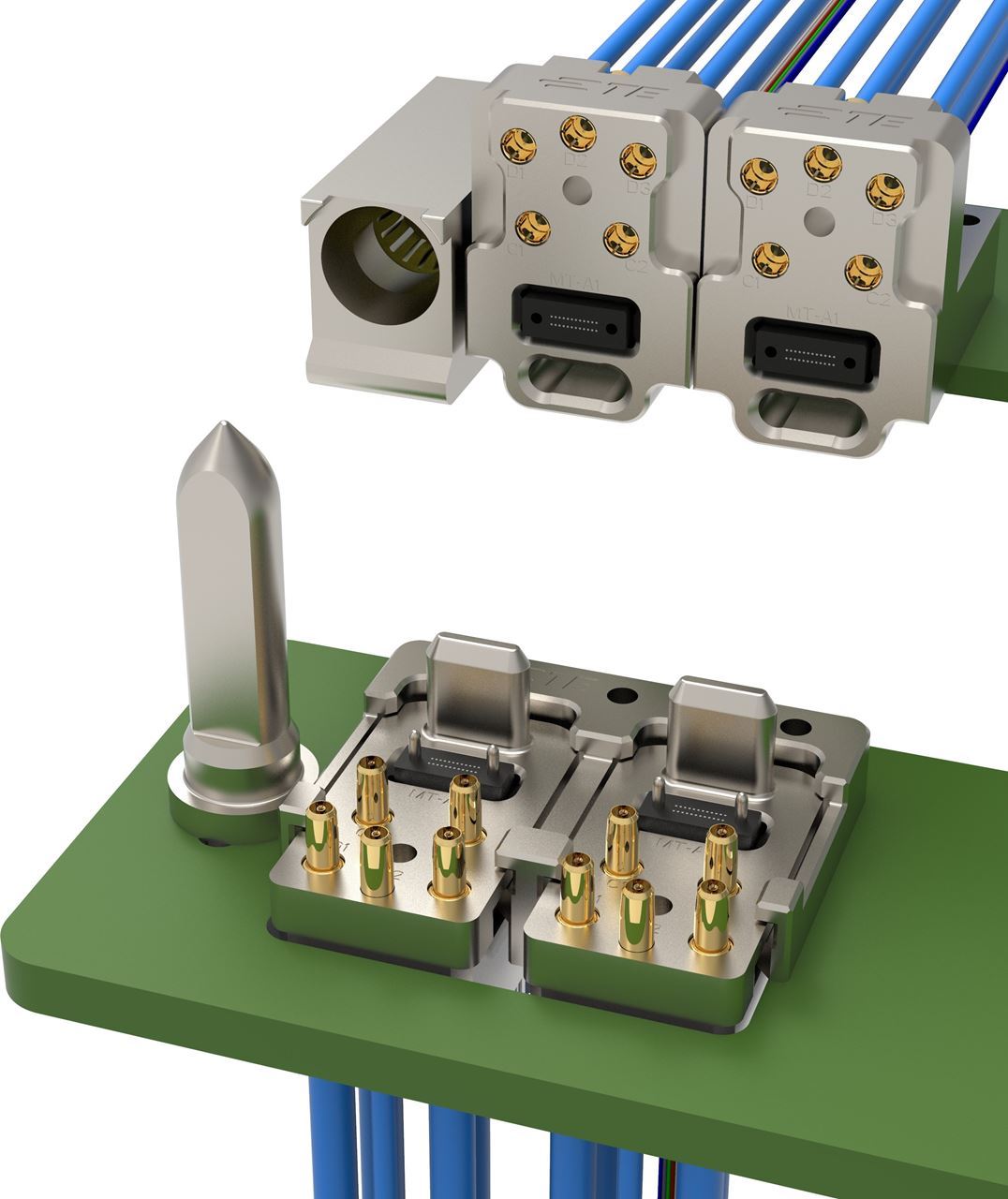

NanoRF modules and contacts provide a rugged, high-frequency nano-miniature coax system that supports two to three times the density of legacy VITA 67 RF modules, which use the SMPM RF contact interface. (Figure 1) Supporting frequencies up to 70 GHz, half- and full-size NanoRF modules can retain up to 12 or 21+ RF contacts—with custom options for even higher counts. A floating insert within the backplane module pre-aligns the RF contacts to assure reliable engagement with minimal wear.

SMPS is another high-density RF interface option in the latest VITA 67.3 draft revision. SMPS uses the radial float of the individual contacts within the module to provide the alignment in mating, similar to SMPM contacts, but on a smaller scale.

Figure 1: NanoRF modules can support two to three times the density of legacy VITA 67 RF modules. (courtesy TE Connectivity).

VITA 66 (ANSI/VITA 66.0-2016) defines a family of blind mate fiber optic interconnects for VITA 46 backplanes and plug-in modules. Once again, the demands on optical solutions are increasing because faster speeds and lighter weight are becoming more critical. Optical transceivers must support higher temperature ranges and more rugged environments.

To boost performance, the density of optical modules is increasing dramatically. Consequently, mechanical transfer (MT) modules for multi-fiber terminal ferrule connectors at the VPX backplane interface are doubling or tripling in the same physical space on the boards. Plus, fiber counts per MT module are increasing from 12 to 24 to 48.

To further support this drive for higher density, new connector module designs are integrating RF and optical signals in a common block for the backplane interface. The block uses less space in a slot versus conventional side-by-side solutions. To enhance reliability, optical cable routing technology—like optical flex circuit cable assemblies—can help manage fiber routing, control bends and stabilize fibers.

VITA 42 (ANSI/VITA 42.0-2016) defines the switched mezzanine card base specification for XMC cards—a peripheral component interconnect (PCI) form factor used in VPX architecture for high-speed serial fabric interconnection. VITA 61 (ANSI/VITA 61.0-2011 (R2014)), or XMC 2.0, uses the VITA 42 architecture, but with a multi-point contact interface targeted for harsh environments.

The use of FMC (FPGA [field programmable gate array] mezzanine cards) and XMC cards are driving faster signals in these interconnects between mezzanine boards and the carrier cards. As a result, connectors are being developed to support higher speed protocols, such as PCIe Gen 4 and Gen 5.

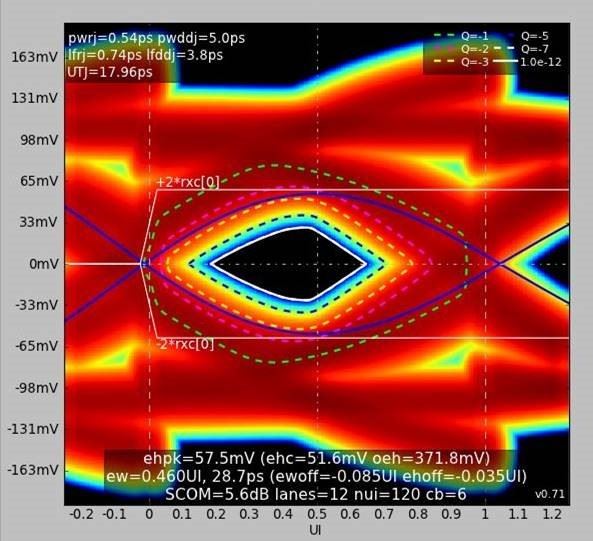

“Next-gen” VITA-compliant products are not just enabling high-speed interconnects as a way to get signals reliably from point A to point B—they are a critical link in the channel. Signal integrity optimization of the interconnect is increasingly important as speeds increase, which can be demonstrated by eye diagram analysis of data signal noise at high speeds. (Figure 2)

Figure 2: As demonstrated by eye diagram analysis of data signal noise, optimizing interconnects is critical for maintaining signal integrity at high speeds (courtesy TE Connectivity).

Ultimately the connector needs to be modeled and tested in a channel and not treated as a standalone component. As an example, multiple iterative MULTIGIG RT 3 connector designs were subjected to over two years of signal integrity analysis done by TE to optimize and verify performance before its final release.

Developments in External Interconnects and Cabling

For external connections between boxes, optical cables accommodate lighter, longer cable runs—a big advantage in aircraft and other applications where weight and electromagnetic interference (EMI) are issues. Rugged termini packaging can also be an advantage. For example, TE’s MC801 connector family combines the high-performance of ARINC 801 optical termini with a rugged MIL-DTL-38999 Series III connector style to ensure secure high-speed data and signal transfer in critical communications systems.

High-speed copper cabling is an option for high-speed protocols, such as 10 Gb/s Ethernet, IEEE 1394, Fibre Channel and USB 3.0. Compared to optical fiber, copper cabling is lower cost because transceivers for electrical-optical conversion are not needed. Moreover, high-speed copper can support higher data rates with next-gen interconnects that reduce signal loss and noise as well as optimize impedance through the cable and connector.

VITA 87 is a draft standard for circular optical MT connectors. Similar to how VITA 66 is addressing fiber density in the optical interface to the backplane, VITA 87 accommodates multiple MT ferrules in proven circular M38999 shells for high density external cabling. The designs in this draft standard include size 11, 13 and 15 shells with 1, 2 and 4 MT ferrules, respectively. These configurations support up to 96 in a single M38999 size 15 connector – the result is significant bandwidth going outside the box, while minimizing panel space.

Ready for Tomorrow’s Embedded Systems

It’s true--the pace of change is challenging for designers of military embedded systems. But evolving VITA standards for OpenVPX have enabled the introduction of numerous “next-gen” products. In the connector realm, specifically, newer, faster and better interconnect technologies have been incorporated into the long-term vision for open standards-based critical embedded systems. As a result, it’s getting easier to meet demanding requirements without resorting to custom solutions that put projects on a costlier, slower track.